What are the performance of Compound fertilizer equipment, Compound fertilizer equipment

Compound fertilizer equipment

Compound fertilizer equipment is a device for making Chemical Fertilizer with pinetic and amino jelly.

Brief introduction

Compound fertilizer equipment: turning drum steam granules production of high concentration Compound fertilizer technology, disc steam -free granular production high, medium and low concentration Compound fertilizer process, Compound fertilizer anti -node block technology, high nitrogen Compound fertilizer production technology, Urea melting spray spray spray sprayThe production of organic inorganic Compound fertilizer technology, etc., has filled the domestic gap.

Nowadays, pinetic and ammonia jelly gymnamics appear in the Compound fertilizer equipment market. They are suitable for domestic markets and are more applicable to large, medium and small enterprises in China.

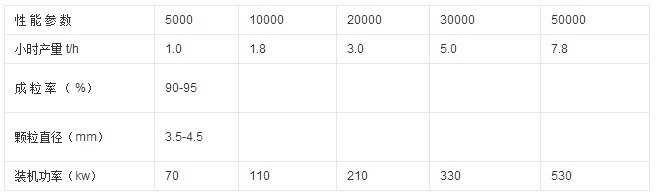

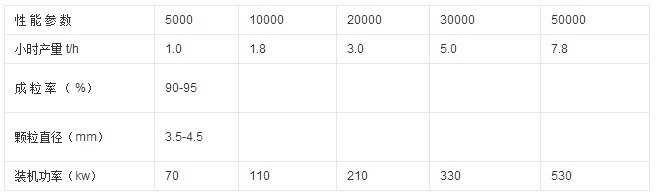

parameter

Craft

Fermentation process

The production process of Organic fertilizer is mainly to lower the moisture content than lower than60%Organic solid waste is mixed and uniformly mixed with auxiliary materials (plant straw, etc.), microbial fermented bacteria, etc., and continuously fermented through pool -type oxygen to make it fully rot, sterilize, deodorize, and remove water.Rotten material moisture content is general30-35%Within the range, it can be directly used to produce spherical organic Fertilizers after screening and magnetic selection, or after further drying the powder and organic production.

Granular process process

The process of Compound fertilizer can be divided into: raw materials, mixing raw materials, raw materials, granules, granular drying, granular cooling, granular grading, finished envelope, and final finished packaging.

1, Raw ingredients:

Hulmum, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (one ammonium phosphate, cyclistan, severe calcium, general calcium), potassium chloride (potassium sulfate) and other raw materials are equipped at a certain proportion (according to market demand and soil in various placesTest results).

2, Stir in raw materials:

Stir well raw materials to improve the uniform Fertilizer content of the overall Fertilizer particles.

3, Raw material granules:

Send the raw materials that are mixed evenly into the granulator (can be used to make granulation, or squeezed granules)Essence

4, Granules drying:

Send the granular particles into the dryer to dry the water contained in the particles to increase the strength of the particles and make it easy to save.

5, Granules cooling:

The temperature of the dry Fertilizer after drying is too high, and it is easy to make the mass. After cooling, it is easy to store and transport.

6, Granular grading:

The cooled particles are graded, and the unqualified particles are crushed and re -made of granules, and the qualified products are divided.

7The finished film film:

increase the qualified products to increase the brightness and roundness of the particles.

8, Finished packaging:

Put the wrapped particles in the finished product in the ventilated place.

Characteristic

1The application of raw materials and its extensive: suitable for fermented livestock and poultry feces, sugar factory filter, urban sludge, papermaking sludge, lees, straw, grass charcoal and other moisture content30%The left and right crude fiber organic waste is directly made of organic waste, which can produce pure Organic fertilizer, organic inorganic Fertilizer, and Organic fertilizer of ball -type particles.

2, High survival rate of ball succession and biological bacteria: new crafts90-95%Above, new technologies for low temperature and large air volume drying can make microbial bacteria achieve the survival rate90%above.

3Short process process: Low operating costs The organic raw materials used in this process do not need to be treated in the early stage of drying, crushing, etc. The process process is short, and the operating costs are low (if traditional granulum manufacturing processes such as discs or drums are used30%The left and right organic raw materials are dried until13%Below, shatter80At the top, and the amount of organic materials cannot be greater than30%To.

technology

Tube reactor technology

This setNPKProduction device selection to introduce the world's advanced Norwegian Heidiru (Hydro) The company's "Tube reactor" patented technology, including hardware and process software packages.This patented technology is more traditional and neutralized.The ammonia grainization process has great advantages in terms of product quality and other aspects.Its characteristics are:

Advanced granules

According to the nutrient requirements of Compound fertilizer products, various liquids and solid materials measured by microcomputer ingredients are synthetic Compound fertilizer in chemical reactions in granulators and Tube reactors, which are continuously wrapped in ammonia grains and obtained a complete global shapeThe particles of particles can reach standards for various nutrients, and it is stable and guaranteed.

Balanced amount of product granules

Because it is chemical synthetic granules, the nutrient content of granular Fertilizers is the same as the logo. It can provide crops with nitrogen, phosphorus, potassium and other nutrients at a certain proportion to ensure the balanced growth of crops.

Good product physical character

The size of the product particles is evenly distributed,90%The particle size is2-4mmGranules; high particle strength, good liquidity, and not crushing when transportation, storage and stacking.The Third design Institute of the Ministry of Chemical Industry has also incorporated France in the engineering designAZFCompany and SpainincroThe company's advanced technology has further optimized the design performance of the device.

Melving urine granules

The device uses melting urine granules, which can meet the requirements of the production of various high -nitrogen nutrient compound Fertilizers on the one hand; on the other hand, it can further improve the quality of granules, make the quality of Fertilizer particles more balanced, Smooth surface, high gloss, and high glossEssence

New technology

New technologies of spraying gallery in spraying of amine pipe reactors, this technology solves the widespread equipment scar, poor production environment, poor adaptation to raw materials, poor product appearance and nutrients in the production of urinary base compound fertilizersPoor problems such as long -term stable operation. This process makes full use of public projects such as steam, urine, air ammonia, air, circulating water, and electricity of Urea enterprises, which can greatly reduce the investment and operating costs of fixed assets.

First, the main feature of the new process of the production process of pillar spray plasma granular Compound fertilizer:

1, Use Tube reactor and air ammonization technology to improve the characteristics of granular materials and granular conditions, granularity temperature70-80, granular ball rate70-80%Essence

2Use a section of high -efficiency drying technology to improve the drying intensity, and the product's moisture reaches1.5%Essence

3The hot air furnace adopts clean fluid bed combustion technology to improve the heating effect, tonfei coal consumption15kgEssence

4The system repurchase uses thermal screening and hot -grained large -grained crushing technology to make full use of the system heat.

5, Improve the screening efficiency and the uniformity of product particles,2.0-4.0mmGranules98%Essence

6Cooling uses unique and efficient new technologies to reduce the packaging temperature as much as possible.

Second, the operating characteristics of new processes of pillar spray plasma pelvic Compound fertilizer:

1, The product is not closing.Product moisture1.5%, Product packaging temperature40, product particle strength25N, The outside of the product is Smooth and round, the particles are uniform2.0-4.0mmGranules98%The product can be treated for half a year without closing the product.

2The range of nitrogen content in the product is large, and the nitrogen content can reach30%, You can produce ternary compound Fertilizers (such as30: 5: 5), Can also produce unit Fertilizer (such as granular nitrogen fertilizer25: 0: 0) And dual Compound fertilizer (such as30: 0: 5To.

3The product variety is convenient to switch. It can produce multi -variety and multi -type Compound fertilizer products, which can produce urine -based types, and can also produce chlor -based types. It can also produce sulfur -based and nitro -type.

4The production system is elastic and has strong adaptability to raw materials.

5, Expand the variety of raw materials, low -priced raw materials such as wetmillium chloride, wet potassium chloride, general calcium, calcium magnesium phosphate Fertilizer, and calcium phosphate can be used in large quantities.

6, The equipment is not scarred or blocked, it can achieve continuous and stable operation of long cycle.

7, Simple process process, convenient maintenance operation and production management, good production environment, can achieve standard discharge and clean civilization production.

8Investment and operation are the most economical.Compared with the same type, fixed asset investment decreases30%Above, the area of land is reduced50%, Calling Consumption Decrease50%, Reduce power consumption25%, A decrease in the cost of Fertilizer tonnage50-75Yuan.

Third, practical situation

Most of the technologies in this process have been successfully put into operation on multiple domestic urine -based compound Fertilizers, and have highlight the distinctive advantage.This process is very suitable for the new urine Compound fertilizer project of Urea companies, and it is also suitable for upgrading and reconstruction of non -Urea enterprises and existing Compound fertilizer production devices.

DCSControl technology

According to the production characteristics of this device, set the phosphate,NPKControl room, adopt a decentralized control system(DCS).Through the full process of dynamic screens, abrasive, phosphate, and sulfuric acid/ /Phosphate area,NPKConcentrated surveillance and control of the device.In control roomCRTIt can display the operating status of various process parameters and machine pumps on the top; automatic control of important process parameters, the start and stop of the main machine pump can be performed in the control room;DCSPowerful functions can print multiple specifications of production reports regularly or in a timely manner; they can timely display parameters, production accidents or system failures; can store and display historical trends, and provide rich operation guidance information; easy to operate and maintain.

DCSThe main function of the operation station:

Display and more limited alarm of process parameters;

It can be easily operated on the control loop, such as adjusting the setting value;

Real -time records and trend records of important parameters;

The operation and display of the operating equipment;

The switch operation and location display of the valve;

System failure self -diagnosis;

Process process screen display;

Control loop screen display;

Timing printing form.

DCSControl technology production devices are adopted in the whole process of raw ingredients and production process adjustment controlDCSMicrocomputer control technology significantly reduces the phenomenon of nutrient ratio and unstable production operations due to incorrect artificial or mechanical measurement ingredients and artificial operation errors.Ensure that the production of the device is stable, the product nutrient ratio is accurate and the standard is met.

Coating film package technology

The device coating film packaging system adopts the latest scientific research achievements of the National engineering research Center of the Feds of Feds and Catalysts -active packaging agents, and uses high -quality parcel powder to enable the product to effectively prevent moisture absorption and granules with each other.Good sex, convenient for fertilization operation, and further improved appearance quality, meeting users not only requires that the internal quality is up to standard, but also pursue the quality requirements of external beauty.

benefit

Analysis of social benefits

How to make full use of the resources of organic waste is an important issue in my country to establish a resource -saving society, promote the circular economy and develop organic agriculture.my country is a large country with Fertilizer consumption. The production of chemical Fertilizers must consume a lot of non -renewable resources such as coal, electricity, and natural gas. The development of this project uses solid organic waste to produce ball -type particle organic Fertilizers to achieve the purpose of saving non -renewable resources and protecting the environment. The social benefits are huge, which is in line with my country's energy conservation and emission reduction industrial policies.

Ecological environmental benefits

Increasing the application of Organic fertilizer can effectively solve the pollution caused by organic waste such as livestock and poultry breeding, reduce the nitrate content of groundwater, and reduce the nutritionalization of surface water body caused by surface source pollution.The safety and quality of agricultural products, the prevention and treatment of contamination, and the efficiency of ecological environment is extremely significant.