Small rockery bonsai production large -scale cement rockery production process teaches you to make various types of rockery

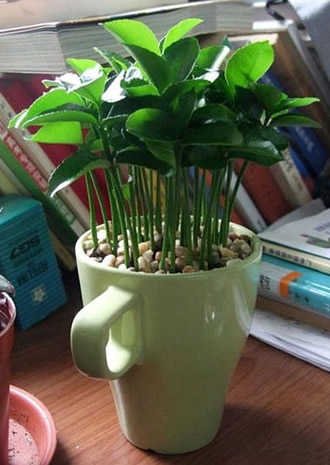

1. Small rockery bonsai production Daquan

1. bonsai selection

In the production of small rockery bonsai, you must first choose the basin. The bonsai is very particular about the combination of the pots and the shelf. The pots are generally purple sand pots, disks, marble disks, stalactites "cloud plates", water grinding stone plates, etc.Most of the shallow plates commonly used in bonsai are rectangular or waist circular. There are four bottoms below. The edges are protruding and multi -edge along the plates to enhance the decoration, white or light blue, and can display the water surface.As for the furnishing pots, the material can be taken on the spot, creating several local characteristics.

Before the production of small rockery bonsai, it is necessary to determine which bonsai shape must be determined. According to the concept, the shape of the mountain is initially placed in the sand table.Note: The height and size of the rockery must be coordinated with the size of the shallow pot.

3. bonsai production

(1) Plastic piercing mountain body: first adjust the cement glue, pay attention to the consistency of the glue, and use it with the adjustment.

(2) Stone processing: Mountains that need to be adapted with hammer, chisel, sawing and other tools to process texture and strange shapes.

(3) Adhesive mountains: Painted with cement glue on both sides that need to be bonded to make the mountain stones consolidate into one, try to make the mountain stones not see the traces of the break.The pulp is cleaned.

After the production of small rockery bonsai, learn to maintain. The flowers and plants configured in the rockery bonsai are small and delicate. Because the soil has a small water storage, it cannot withstand the exposure of the strong sunlight. It can only see the appropriate sunlight.Therefore, it is necessary to strengthen the shade, especially in the summer, which must be maintained under the shade shed, otherwise, the moss of the flowers and trees will be dry, atrophy, and soil surface.

At the same time, exposure will also make the ornaments on the bonsai lose color, peeling, and break, making the entire bonsai lose the value of ornamental.The Outdoor management of the rockery bonsai should be screened for rains, and it should not be too fierce during watering. Otherwise, it will rush to the pot mud and affect the growth of the plant.

When giving water, it is best to use water spraying or watering methods. This is not only conducive to the growth of plants, flowers and plants, and moss, but also wash off the dust on the surface of the rocks to keep the entire mountain stone fresh and green and vibrant.

Tips: Water can be stored in small rockery bonsai, or it is decorated with pavilions, boat bridges, characters, and other non -structural parts. It is also equipped with trees or small plants. After art processing, Make the beauty of the mountains and rivers are concentrated, reproduced in the pot.

Second, small cement rockery production process

1. Positioning sample: Position samples according to drawings, models and on -site conditions.

2. Buried parts: The cast-in-law uses 70 100 6 embedded parts, with a spacing of 1.5-2.5m buried; the framework of the frame is 70 100 6 embedded parts, and the spacing is 2m buried.Before burial, the rust, oil stains, and paint on the surface of the concrete should be cleaned up. The burial parts should be reinforced firmly before covering, and the specifications, quantity, location and location and location of the embedded parts should be connected to the concrete steel bars.Buried depth should meet the requirements of the design drawing.

3. Something production: The main material is 50 50 5 angle steel. The secondary point is used at 30 30 3 angle steel to apply rust paint for rust treatment.The premium of the plastic stone Square skeleton, the spacing size of the skeleton corner steel is generally controlled: the horizontal spacing is 1.3m, and the vertical spacing is 1.3m.The connection is welded; and then the left and right stackers are performed according to the model to make the rigid shape of the rockery.

4. Steel mesh: The wire mesh used in cement rockery is generally the most suitable mesh and wire diameter of 6mm.After the production of the skeleton is completed, the steel wire mesh is made with 6 round steel. The steel wire mesh is controlled at about 18 18-25 625px. The natural shape of the initial convex and concave is shaped according to the model.

5. Tie wire binding: After the wire mesh is covered with the rockery, the wire with a specification of 3 1/4 (4 meters) is tied to the rockery skeleton firmly.

6. Plasma: Hanging cement mortar to form stone veins and wrinkles. The fibericity can be added to the cement mortar to increase the power of the surface and reduce the crack.The wire is bundled and is completed, and the grassroots plastering is used with concrete mortar, with a thickness of about 1-37.5px; after the first completion, the second placement is performed with a thickness of about 37.5px.After the two layers of plastering of the rockery are completed, the wipes of the mortar inside the rockery in a timely manner are about 25px.The detailed operation steps are as follows:

(1) 1: 1.5 Composite cement mortar is scraped and covered with the steel wire mesh. The thickness is about 1cm. After full, it needs to be maintained for 2 days.

(2) 1: 2 ordinary cement mortar supplementary sewing.

(3) 1: 1.5 ordinary cement mortar plastic fake mountain texture. The artwork uses a variety of craftsmanship and other techniques to make fake mountain texture, which is about 2cm thick.maintenance after completion for 3 days.

(4) 1: 3 ordinary cement mortar repair texture and cracks.

7. Style: According to the model and the material of the mountain stone, the shape of the plastic stone rockery is shaped to shape the stone veins and stripes.The texture, color, texture and surface characteristics of the stone are carved on the surface of the plastic stone.According to the design requirements, the texture and color are mortar with stone powder and color powder with white cement or ordinary Flour according to the appropriate proportion, and treat plastic facial methods such as rough, Smooth, and hair.The shaping of texture, generally speaking, straight lines and stones supplemented by horizontal patterns are more able to express a steep and upright posture; mountain stones that are mainly horizontal and unsuited by straight lines are more expressive and bold.Comprehensive patterns of mountains and stones are more deep and magnificent.In order to enhance the natural and authenticity of mountain stones, in addition to the texture of texture, the natural characteristics of mountains and stones must be made, such as seams, holes, holes, rot, cracks, faults, displacement, etc.Generally speaking, the texture of the texture should be used to summarize the simplified refining; the processing of natural characteristics should be carefully carved with the "gongbi" method.

8. Coloring: According to the position of the plastic mountain stones, choose the appropriate iron oxide pigment for modulation and coloring.When the plastic stone water is not dry, the basic color calls the pigment powder and cement with water and mix well, and sprinkle the stain layer by layer.The coloring steps are as follows:

(1) The closed back color is blocked.

(2) Once color (3 layers).

(3) Two -color replenishment (dark color).

(4) Spray surface oil sealing color.Slightly darker tones are sprinkled slightly in the stone seam holes or the corners. When the plastic stone is 90 % dry, a little green, black or white and other sparse spots are sprinkled on the depression to enhance the three -dimensional and natural sense.

9, noodle oil: noodle oil can maintain the luster of stones to avoid the oxidation and weathering of stone Skin.Common use of maintenance oils include Vaselin, oil wax, light wax, etc., dipped in wax with gauze, and lightly wipe it lightly.

10. Rocket maintenance: Start maintenance after the cement is first condensed. It should be covered with hemp pockets, grass curtains and other materials to avoid direct sunlight and sprinkle water every 2-3 hours.Pay attention to lightly when sprinkled water, and cannot shoot.The maintenance period is not less than half a month. When the temperature is lower than 5 C, sprinkle water should be stopped. Anti -frozen measures, such as covering straw, grass curtains, grass Bags, etc.